Oxygen Analyzer

Introduce of Oxygen Sensor and Oxygen Analyzer

Oxygen Sensor

The oxygen sensor is simply a sealed container (metal or plastic container), which contains two electrodes: the cathode is a piece of PTFE (polytetrafluoroethylene) coated with an active catalyst, and the anode is a lead block. This sealed container, there is only a capillary pore on the top, allowing oxygen to pass through the working electrode. The two electrodes are connected to the two protruding pins on the sensor surface through the current collector, and the sensor is connected to the sensor on the applied device through these two antennae. The electrolyte solution is filled so that different ions can be exchanged between the electrodes.

The flow rate of oxygen entering the sensor depends on the size of the capillary pores on the top of the sensor. When oxygen reaches the working electrode, it is immediately reduced to release hydroxide ions:

O2 + 2H2O + 4e- “type =” #_ x0000_t75 “> 4OH-

These hydroxide ions reach the anode (lead) through the electrolyte and undergo an oxidation reaction with lead to form the corresponding metal oxide.

2Pb + 4OH- “type =” #_ x0000_t75 “> 2PbO + 2H2O + 4e-

The above two reactions generate a current, and the magnitude of the current depends on the oxygen reaction speed (Faraday’s law). A known resistance can be connected to measure the generated potential difference, so that the concentration of oxygen can be accurately measured in the electrochemical reaction. The electrode participates in the oxidation reaction, so that these sensors have a certain life span. Once all available lead is completely oxidized, the sensor will stop functioning. Generally the service life of the oxygen sensor is 1-2 years, but it can also be increased by increasing the anode lead. Content or limit the amount of oxygen in contact with the anode to extend the life of the sensor

Capillary oxygen sensor and partial pressure oxygen sensor

The oxygen sensor produced by City Technology is divided into two types according to the diffusion of the oxygen entering the sensor. One is a capillary hole on the top of the sensor, and the other is a solid film that allows the gas to measure through the hole sensor. Is the oxygen concentration, and the solid film sensor measures the partial pressure of oxygen

The current produced by the pore sensor reflects the volume percentage concentration of the measured oxygen, which has nothing to do with the total pressure of the gas. However, when the oxygen pressure changes momentarily, the sensor will generate an instantaneous current. If it is not controlled, a problem will occur. The sensor also appears when it is subjected to repeated pressure pulses. For example, the gas entering the sensor is pumped. The explanation of this phenomenon is as follows:

Pressure transient

When the fine-hole oxygen sensor encounters a sudden pressure increase or decompression, the gas will be forced to pass through the fine-hole grid (large flow). The increase (or decrease) of the gas generates a transient current signal. Once the situation is stable again, there is no pressure pulse. , The transient is over. Such transients can be alarmed by the instrument, so CityTech can work hard to find solutions to reduce the impact of stress

All urban technology’s fine-pore oxygen sensors use a high-flow resistance mechanism. See Figure 2. Basically, a PTFE anti-high-flow film can be added to reduce the transient effects of pressure changes. This film is covered with a metal cap or plastic. The cap is tightly fixed on the fine hole. This design can greatly reduce the effect of transient changes in the signal.

However, the transient force generated by some pressure changes exceeds the allowable range of this design, especially the equipment that uses the pumping instrument to send gas to the sensor. The gas generated by some pumps causes continuous pressure pulses to the CiTiceL oxygen sensor, which is artificially enhanced. In this case, it is necessary to design a gas expansion chamber outside the sensor to reduce the pressure pulse on the sensor.

Partial pressure type oxygen sensor

Capillary pores controlling gas diffusion is not the only way to control oxygen entering the sensor. We can also use a very thin plastic film to cover the top of the sensor to disperse oxygen molecules before entering the sensor. Gas sensor German rbr EN2 integrated flue gas analyzer German rbr CN handheld flue gas analyzer

Classification and characteristics of oxygen sensors

There are two kinds of practical oxygen sensors: zirconia oxygen sensor and titania oxygen sensor. The common oxygen sensor is divided into single lead, double lead and three leads; single lead is a zirconia oxygen sensor; double lead is a titanium oxide oxygen sensor; three leads are heated zirconia oxygen sensor, In principle, the three-lead oxygen sensor can not be used instead.

Zirconia Oxygen Sensor

1. Structure of zirconia oxygen sensor

The zirconia oxygen sensor is mainly composed of zirconia (ZrO2) and sheath. There are two types of zirconia oxygen sensor: heated and non-heated. The heated oxygen sensor has a heating rod in the middle of the zirconium tube. The zirconium tube is made of ceramic body and fixed in a fixed sleeve with mounting threads.

The guide row is inserted into the exhaust pipe, its inner surface is in communication with air, and its outer surface is in communication with exhaust gas. The inner and outer surfaces of the zirconium tube are covered with a layer of porous platinum film as an electrode. In order to prevent the exhaust gas from corroding the platinum film, the platinum film layer on the outer surface of the zirconium tube is covered with a porous ceramic layer, and there is a protective sleeve There are notches or holes on it. The terminal of the oxygen sensor has a metal sheath with a hole on it to allow the inner surface of the zirconium tube to communicate with the air. The platinum electrode on the inner surface of the zirconium tube is led out of the sensor through an insulating sleeve.

2. Features of zirconia oxygen sensor

Advantages: simple structure, quick response, easy maintenance, convenient use, accurate measurement. Using this sensor to measure and control the combustion atmosphere can not only stabilize and improve product quality, but also shorten production cycle and save energy.

Disadvantages: The disadvantage is that this characteristic is fully manifested only when the temperature is high (about 600 ℃). At low temperatures, this characteristic will change greatly.

Titanium Oxygen Sensor

1. Working principle of titanium oxide oxygen sensor

Compared with the zirconia type oxygen sensor, which generates a voltage signal, the titanium oxide (TiO2) type uses the change in resistance to determine the oxygen content. Above a certain temperature, the combination of titanium and oxygen is weak. In the case of very little oxygen, the oxygen must be abandoned, so the lack of oxygen forms a low-resistance oxide semiconductor.

Conversely, if there is a lot of oxygen, a high resistance state is formed. Just like the water temperature sensor, there is a change in the resistance level. At this time, as long as a reference voltage is supplied, the temperature of the cooling water can be known from the voltage.

2. Features of titanium oxide oxygen sensor

The working principle of the titanium oxide type oxygen sensor is very different from that of the zirconium oxide type oxygen sensor. It is made by using the characteristic that the conductivity of the porous conductor TiO2 changes with the change of the oxygen content in the exhaust gas, so it is also called resistance Oxygen sensor.

The structure of this kind of sensor is simple, small in size and low in cost, but when working at 300 ℃ ~ 900 ℃, the resistance value changes greatly with temperature, so you must use temperature compensation to improve accuracy, usually another solid TiO2 conductor as Temperature compensation.

Features and Products of Oxygen Analyzer

Oxygen Analyzer Function Features and Product Introduction

Features:

◆ The sensor and transmitter adopt an integrated structure, and the aluminum alloy case is lighter and smaller than similar instruments.

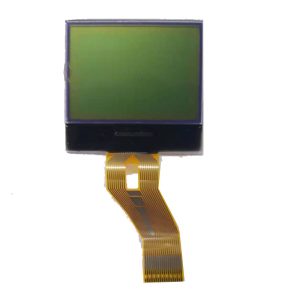

◆ Large screen LCD dot matrix display, man-machine dialogue

◆ Chinese menu-style function selection

◆ Automatic measurement data storage, with paperless recorder function

◆ Arbitrary setting of measured value upper and lower limit alarm output

◆ Automatic range switching

◆ Communication RS232

Product description:

The zirconia oxygen analyzer is an oxygen sensor composed of a zirconia solid electrolyte, and the signal change is an intelligent online analysis instrument composed of a new microprocessor as the core.

The main purpose:

◆ Air separation, automatic analysis of oxygen content in chemical process

◆ Production of semiconductors and magnetic materials

◆ Float glass and cement building materials industry

◆ Automatic analysis of oxygen content in various industrial furnaces and heat treatment processes

◆ Scientific research on electronic components, biopharmaceuticals, etc.

Showing 1–12 of 13 results