Vacuum Valves

The definition of the vacuum valves

Vacuum valves are an essential component in any vacuum system. There are a variety of different types. And they fall into three main categories. The three caregories are operational valves, closing valves and sealing valves.

The selection of the proper valve type requires an understanding of the process application. So that we can choose the proper design

and/or functioning valve for a given vacuum furnace operation.

When talking about vacuum valves the ones that most people think of are those installed in lines. They connect a vacuum chamber to a vacuum pump.

They are three valves. The first is the roughing valve

(aka main valve if a diffusion pump package is not installed). The second is the poppet (aka the main valve). The last is the foreline valve and the holding valve.

The gas evacuation path is different during initial pump down (aka roughing). The pump is with gas moving through the mechanical pump line. The poppet value is closed as opposed.

When the diffusion pump is activated and the poppet valve is open. And the flow is through the diffusion pumps for high vacuum capability.

What is a vacuum valve?

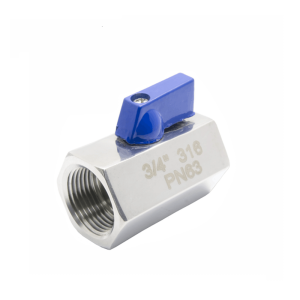

A vacuum valve is a device. We place it in a feed or vent line on a vacuum furnace. Its purpose is to isolate the vacuum chamber or direct the flow of gas into the vacuum vessel. We can actuate these valves manually, pneumatically, electropneumatically, electrically or electromagnetically.

We can install a series of pressure switches in most lines with vacuum valves (other than manual valves). They can control the flow and changing the internal furnace pressure. We demand the pressure by the process being run.

Due to the nature of vacuum, it is necessary to choose a vacuum valve. It is capable of working in the operating vacuum range of the furnace. The knowledge of the application end. Using a given vacuum valve is key to determining the right vacuum valve.

How to use a vacuum valve?

We use the roughing valve when evacuating a vacuum furnace chamber from atmospheric pressure. It is a so-called “rough” vacuum (typically in the range of 10-2 to 10-3 Torr).

In some instances, this level of vacuum is adequate to run the intended process. In other applications, a diffusion pump is added to the pumping package. And the roughing pump is used prior to connecting the chamber to the diffusion pump.

The mechanical pump vent valve serves to admit atmosphere to the roughing line. Thus “breaking vacuum” allows the mechanical pump to return to atmospheric pressure. We use the pump when shutting down a vacuum furnace pumping system. Or for maintenance on the pumps or the furnace proper.

If present, we turn off the diffusion pump first and allow the pump to cool. And then we turn off the mechanical pump. Bringing the stopped mechanical pump to atmospheric pressure. It prevents mechanical pump oil from being drawn back into the foreline.

We should clsoe he holding valve and the foreline valve during the operation. Thus we keep the diffusion pump, cold trap and baffle under high vacuum. This assures a clean system when starting up at some later date.

The mechanical pump vent valve serves to admit atmosphere to the roughing line. It brings the mechanical pump to atmospheric pressure. We use mechanical pump when shutting down the system. And turn off the diffusion pump and allow it to cool. Then we turn off the mechanical pump. So we bring the stopped mechanical pump to atmospheric pressure. It prevents mechanical pump oil from being drawn back into the foreline.

Showing 1–12 of 87 results