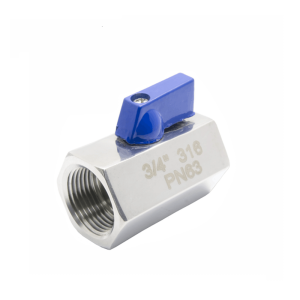

Ball Valves

The definition of the ball valve

A ball valve is a form of quarter-turn valve which uses a hollow. The hollow perforates and pivotes ball to control flow through it. It is open when the ball’s hole is in line with the flow. It is closed when it is pivoted 90-degrees by the valve handle.

The handle lies flat in alignment with the flow when open. And it is perpendicular to it when closed. This makes it easy visual confirmation of the valve’s status. The shut position 1/4 turn could be in either CW or CCW direction. (S = SHUT, O = OPEN)

The advantages of the ball valves

Ball valves are durable, performing well after many cycles, and reliable. They are closing securely even after long periods of disuse. These qualities make them an excellent choice for shutoff and control applications. They are often preferred to gates and globe valves. But they lack their fine control in throttling applications.

The ball valve’s ease of operation, repair, and versatility. The versatility lends it to extensive industrial use. It supports pressures up to 1,000 bar (100 MPa; 15,000 psi) and temperatures up to 752 °F (400 °C). It depends on design and materials used.

Sizes typically range from 0.2 to 48 inches (5.1 to 1,219.2 mm). Valve bodies are made of metal, plastic, or metal with a ceramic. Floating balls are often chrome plated for durability.

One disadvantage of a ball valve. They trap water in the center cavity while in the closed position. In the event of a freeze, the sides can crack due to expansion of ice forming.

Some means of insulation or heat tape in this situation will usually prevent damage. Another option for cold climates is the “freeze tolerant ball valve”.

This style of ball valve incorporates a freeze plug in the side so in the event of a freeze up. The freeze plug ruptures (acts as a sacrificial disk), thus makes it for an easy repair. Now instead of replacing the whole valve, just screw in a new freeze plug.

In the case that a ball valve is used for cryogenics. The product may expand inside of the ball. There is a vent drilled into the upstream side of the valve. This is referred to as a vented ball. Safety is the number one concern when engineers specify a vented ball.

We should confuse a ball valve with a “ball-check valve”. A type of check valve uses a solid ball to prevent undesired backflow.

Other types of quarter-turn valves include the butterfly valve and plug valve and freeze proof ball valve.

There are five general body styles of ball valves. They are single body, three-piece body, split body, top entry, and welded. The difference is based on how the pieces of the valve. Especially the casing that contains the ball itself. They are manufactured and assembled. The valve operation is the same in each case.

In addition, there are different styles related to the bore of the ball mechanism itself. And depends on the working pressure, the ball valves are divided as low pressure ball valves and high pressure ball valves.

The uses of the ball valves

In most industries, people consider the ball valves with working pressure higher than 3000 psi as high pressure ball valves. Usually the max. Working pressure for the high pressure ball valves is 7500 psi. And it depends on the structure, sizes and sealing materials, the max. Working pressure of high pressure ball valves can be up to 15000 psi. People mostly use high pressure ball valves in applications under high pressure. Such as hydraulic systems, so we call them hydraulic ball valves, too.

Ball valves in sizes up to 2 inch generally come in single piece, two or three piece designs. We reduced one piece ball valves. They are relatively inexpensive and generally are throw-away.

Two piece ball valves are generally slightly reduced (or standard) bore. They can be either throw-away or repairable. The 3 piece design allows for the center part of the valve containing the ball. And the stem & seats is easily removed from the pipeline.

This facilitates efficient cleaning of deposited sediments, replacement of seats and gland packings, polishing out of small scratches on the ball. All this without removing the pipes from the valve body. The design concept of a three piece valve is for it to be repairable.

Showing 1–12 of 28 results