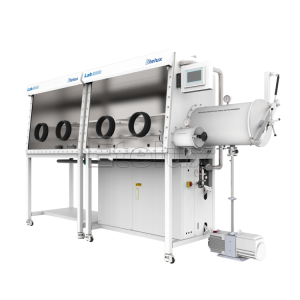

UPM-400 inert gas packaging unit for metal powders is designed for inert-gas packaging and other operations with metal powders. The Unit is equipped with a platform for receiving and unloading of ATT-30V and ATT-30G transport tanks, unloading and packaging is carried out by an integrated screw conveyor.

Technical features and advantages of UPM-400:

- Designed and manufactured specifically for working with metal powders for additive manufacturing, sintering, etc.

- The transparent frontal screen opens for convenient access of operator and maintenance personnel inside the box.

- Control system of oxygen concentration in the chamber. An optional water vapor control system is installed.

- Control of screw conveyor by foot pedal.

- Platform for transport tanks with vibration bypass. The platform is equipped with guides to simplify tank installation.

- High-quality gloves manufactured by Piercan (France).

- Fine adjustment of powder feed rate by frequency converter.

- Full set of technical documentation in accordance with military acceptance standards.

Standard supply package of UPM-400:

- Working chamber (vacuum glovebox).

- Electrochemical oxygen analyzer.

- Screw conveyor with variable frequency drive and the ability to control both by interface on the control cabinet, and by foot pedal.

- Two-cylinder gas discharge ramp.

- Industrial dustproof scales Ohaus (scale capacity 30 kg), scales with other characteristics can be installed on request.

- Gloves from butyl rubber manufactured by Piercan (France).

- Inert gas flow meter.

- LED lighting system for the working chamber.

- Sealing gland.

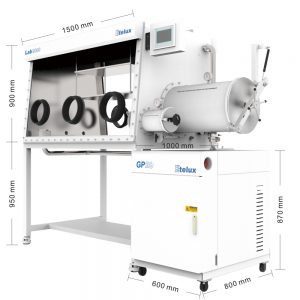

| Name | Value |

| Overall dimensions, WxDxH, mm |

1,880х900х1,780 |

| Working chamber internal dimensions, WxDxH, mm |

1,200х700х700 |

| Material of working chamber housing |

AISI 304 |

| Net weight, kg |

350 |

| Maximum output, L/h |

100 |

| Material particle size, mm |

0,005…5 |

| Glove port diameter, mm |

186 |

| Recommended operating pressure in working chamber, bar |

-0.01 … +0.01 |

| Power supply |

220 V, 50 Hz |

| Maximum input power, W |

1,500 |

Metal powder 3D printing machine

Powder metal printing machines series Alfa – one of the most popular models owing to sufficiently large operating field, which enables manufacture of details ...

Advanced plasma atomization process: How powder is made for additive manufacturing

AP&C is a leader in the production of metal powders for Additive Manufacturing. The APA™ process produces premium quality spherical powders of reactive ...

Atomization Improvements for Additive Manufacturing Applications webinar

Praxair Surface Technologies (PST) is an industry leader of aerospace-grade gas-atomized powders for additive manufacturing (AM). PST maintains expertise ...

Video

Metal powder 3D printing machine

Powder metal printing machines series Alfa – one of the most popular models owing to sufficiently large operating field, which enables manufacture of details ...

Advanced plasma atomization process: How powder is made for additive manufacturing

AP&C is a leader in the production of metal powders for Additive Manufacturing. The APA™ process produces premium quality spherical powders of reactive ...

Atomization Improvements for Additive Manufacturing Applications webinar

Praxair Surface Technologies (PST) is an industry leader of aerospace-grade gas-atomized powders for additive manufacturing (AM). PST maintains expertise ...

The videos are from Youtube. If there is any infringement, we will delete them, please send an email to [email protected], thanks.