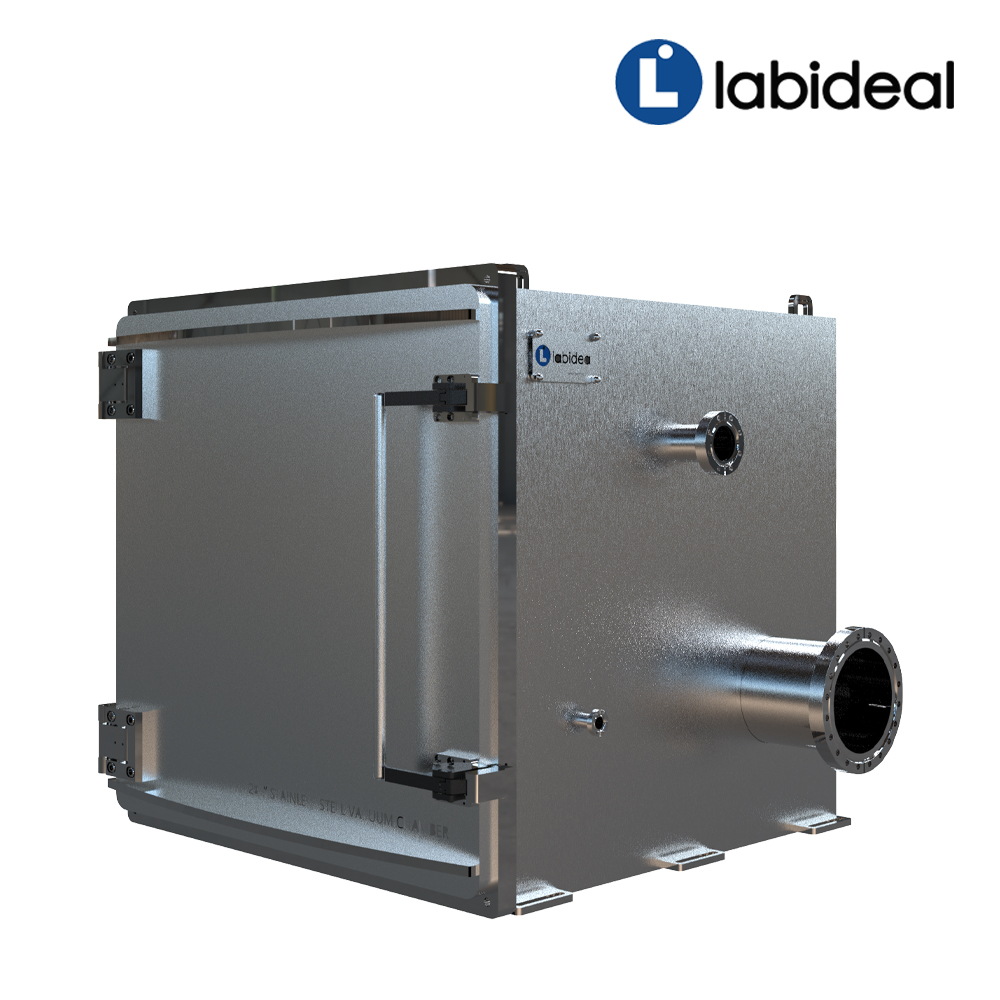

Stainless steel Vacuum Chambers

We will assist you in your vacuum chambers or vacuum components on request. Our teams and facilities are equipped to custom build complete assemblies for your vacuum and high vacuum needs.

Materials : Stainless steel 304L or 316L, Mu-metal (µ-metal).

Manufacturing Capabilities

Chamber Ø : up to 2 m

Internal TIG welding

General surface finish : Ra 3.2

Vacuum sealing faces : Ra 1.6 à 0.8

External bead blast or electropolished

He leaked test control : down to 1.10-10 mbar.l.s-1

Analyse des gaz résiduels (RGA) sur demande

Cleaning and Testing

For smaller Ø : nettoyage avec notre installation de nettoyage automatique (check our video above at 2″09-2″18)

For bigger Ø : nettoyage par jet de vapeur chaude, rinçage, étuvage (pression atmosphérique)

On request:

the cleaning under vacuum can be made with the RGA (up to 380°C).

delivery of the chambers with closing flanges after cleaning under vacuum.

Our cleaning procedure offers ready to use chambers and components with KF, ISO and CF flange.

Quality control / Testing

All of our chambers are checked and tested during and after the manufacturing process. We can provide you, on request :

Material certificate type EN 10204-3.1

Dimensional control report PV de contrôle dimensionnel

He leak test control

Enregistrement de l’analyse de gaz résiduels (RGA)

You can check our video above to watch all of these steps (1″37-2″08).

Showing 1–12 of 14 results