Application of Vacuum Ball Valve

Vacuum ball valve: refers to a vacuum ball valve whose working pressure is lower than the standard atmospheric pressure.

Several common connection forms of vacuum valves

- Flange connection

This is the most commonly used connection form in valves. According to the shape of the joint surface, it can be divided into the following types:

1) Smooth type: used for valves with low pressure. Processing is more convenient

2) Concave-convex type: high working pressure, medium hard washer can be used

3) Tongue and groove type: gaskets with larger plastic deformation can be used, which are widely used in corrosive media and have a better sealing effect.

4) Trapezoidal groove type: Use an oval metal ring as a gasket, which is used for valves with working pressure ≥64 kg/cm², or high temperature valves.

5) Lens type: The washer is a lens shape and is made of metal. Used for high pressure valves with working pressure ≥100 kg/cm², or high temperature valves.

6) O-ring type: This is a relatively new form of flange connection. It is developed with the appearance of various rubber O-rings. It is more reliable than ordinary flat gaskets in sealing effect.

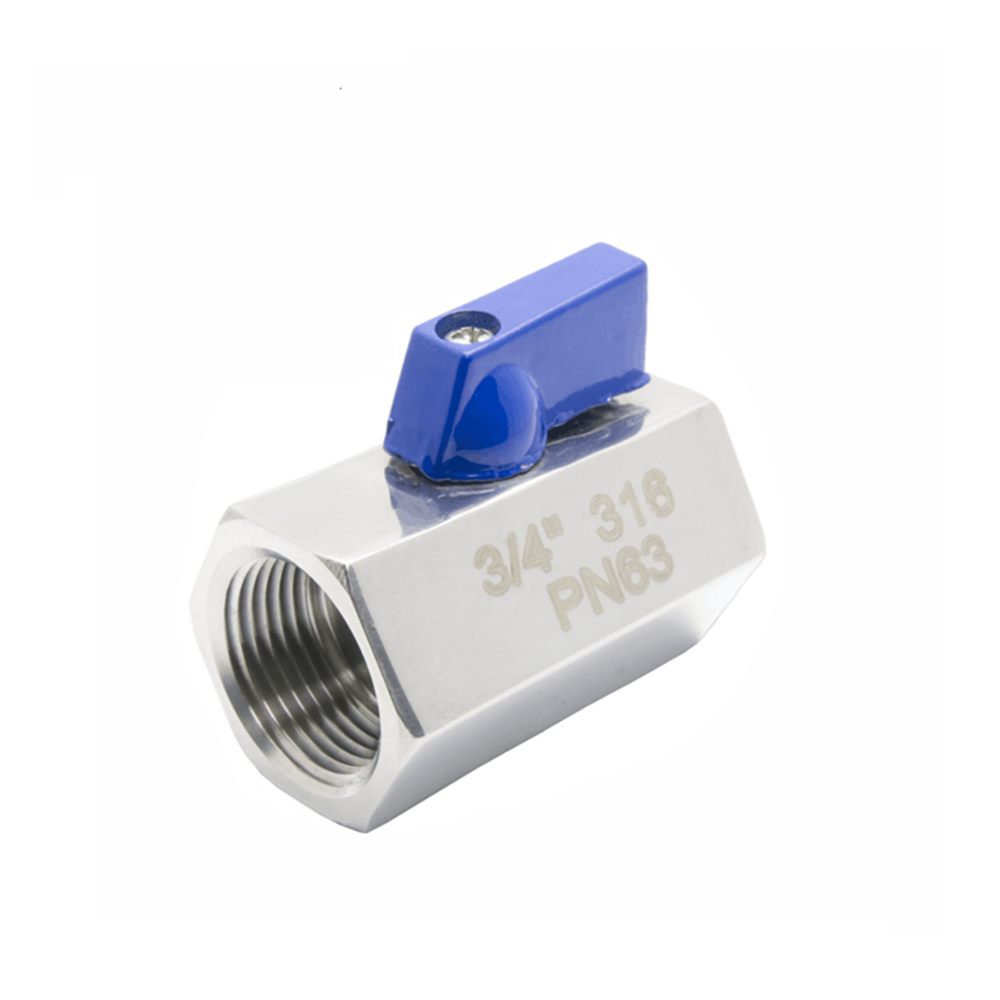

- Threaded connection

This is a simple connection method, often used for small valves. There are two situations:

1) Direct sealing: the internal and external threads directly play a sealing role. In order to ensure that the joints do not leak, they are often filled with lead oil, hemp and PTFE tape; among them, PTFE tape is widely used every day; this material has good corrosion resistance and excellent sealing effect. Good, it is convenient to use and store. When disassembling, it can be completely removed because it is a non-sticky film, which is much better than lead oil and hemp.

2) Indirect sealing: The tightening force of the thread is transmitted to the gasket between the two planes, so that the gasket plays a sealing role.

The role of vacuum valve in vacuum system:

- Open and close the air circuit. When valve 1 and valve 4 are closed and valve 2 is opened, the mechanical vacuum pump III vacuums the container I, and the air flows through the pre-vacuum pumping pipe; when valve 2 is closed and valve 4 is opened, the mechanical pump can Vacuum the diffusion pump separately; when valve 1 and valve 4 are opened at the same time, the diffusion pump and the mechanical pump can work at the same time to evacuate the container, and the airflow flows through the diffusion pump. It can be seen that the function of the valve in this operation is to switch the air path and change the route of the air flow.

- Control the air flow and adjust the vacuum degree. In Figure 1, the opening angle of the valve cover of valve 1 can be adjusted to adjust the air flow through the pipeline; valve 2 and valve 4 are closed, and the air release valve 3 can be used to pump The inlet of III is put into the atmosphere; the vacuum degree in the container can be adjusted through the vent valve 5.

- Quantitative inflation. There is a small hole of a certain volume in the plunger of the glass valve. When the small hole is turned to the right and connected to the high-pressure gas cylinder, the small hole can be filled with high-pressure gas; when it is turned to the left and connected to the vacuum container , Put the volume of high-pressure gas into the container, so it plays the role of quantitative inflation.

There are many types of vacuum valves, which are usually classified according to the valve’s function, structure, drive mode, material and use.

Parameter definition:

- Nominal diameter: (nominal diameter), also known as mean outside diameter (mean outside diameter), represents the symbol DN, which is the general diameter of various pipes and pipeline accessories. The pipes and pipe accessories of the same nominal diameter can be connected to each other, which is interchangeable. It is not the actual pipe outer diameter or inner diameter, although its value is close to or equal to the pipe inner diameter, in order to make the pipe and pipe fittings uniform in size , Adopt the nominal diameter (also called nominal diameter, nominal diameter). For example, welded steel pipes can be divided into thin-walled steel pipes, ordinary steel pipes and thickened steel pipes according to their thickness. Its nominal diameter is neither the outer diameter nor the inner diameter, but a nominal size similar to the inner diameter of ordinary steel pipes. Each nominal diameter corresponds to an outer diameter, and the value of the inner diameter varies with thickness. The nominal diameter can be expressed in metric system mm or in imperial system in. Pipeline accessories are also expressed by nominal diameter, which has the same meaning as a seamed pipe.

- Nominal pressure: (Nominal pressure), which means the symbol PN, the maximum allowable working pressure when applied at a certain temperature. For control valves with carbon steel body, it refers to the maximum working pressure allowed for applications below 200°C; for cast iron valve body, it refers to the maximum working pressure allowed for applications below 120°C; for control valves with stainless steel body, it refers to 250°C below Maximum working pressure allowed during application. When the operating temperature increases, the pressure resistance of the valve body will decrease. For example, a carbon steel control valve with a nominal pressure of 6.4MPa (PN64) has a withstand pressure of 5.2MPa at 300°C, a withstand pressure of 4.1MPa at 400°C, and a withstand pressure of 2.9MPa at 450°C. . Therefore, the nominal pressure of the control valve must be determined not only based on the maximum working pressure, but also based on the maximum working temperature and material characteristics, not just to satisfy the nominal pressure greater than the working pressure.