Metal Powder Atomisation Methods for Modern Manufacturing

The recent upsurge of interest in manufacturing techniques using metal powders, including additive manufacturing (AM), metal injection moulding (MIM) and hot isostatic pressing (HIP), has made methods for manufacturing alloyed metal powders especially iron-, nickel- and cobalt-based alloys, a topic of much increased importance. Drawing on 45 years of experience in the field, the author reviews the range of methods available for this purpose, their advantages and limitations and likely fields of application.

1. Recent Developments in the Powder Metallurgy Industry

Having spent many years working on powder metallurgy (PM) and atomisation, it is very heartening to see the current remarkable upsurge in interest in the field. The ‘classical’ PM sintered parts business did not attract much research interest in the UK in the 1980s and 1990s, but the last twenty years have seen first, the advent of MIM and HIP and, more recently, AM or three-dimensional (3D) printing (1). These have, over the last ten years or so, led to a huge upsurge in research and industrial investment in PM all around the world. These newer branches of PM make quite different demands on the metal powders that they employ. The global volumes of powder consumed are still modest compared to the ‘classical’ PM parts business which accounts for ~1 Mt yr–1 of Fe powder (1), but they have growth rates in tonnage terms of 10–40% per annum and high powder values (typically in the range of €7–200 kg–1 compared with Fe powder’s €1–2 kg–1 (2). Thus there has been a major upsurge of investment in plants to produce such high value powders. However, production capacity for vacuum melted, gas atomised powders is only around 20,000–30,000 tonne yr–1.

2. Demands of the Newer Powder Metallurgy Technologies

The newer technologies have certain features in common, so far as powder quality requirements are concerned, but also some very major differences. The MIM process (Figure 1) consists of blending powder with plastics or waxes, injection moulding oversize parts, removing the binder (debinding) and then sintering the part to full density.

Fig. 1.

The MIM process. Adapted from (3), CC BY-SA 4.0

This requires, above all, fine powders, in order to have the required high degree of sintering activity to allow the green part to be sintered to high density. Typical powders have (mass) median particle sizes of 5–15 μm with maximum particle sizes from 15 μm to 50 μm. The shape of the powder is not a clear-cut demand; high tap density is desirable to reduce shrinkage (typically ~15%) when sintering to full density, but excessively spherical and smooth particles can reduce ‘brown strength’ which is the strength of the components after debinding. Purity demands are moderate, for example oxygen content is not critical, as high temperature sintering allows reduction of most oxides. Alloys include low alloy steels, a lot of stainless steels (~50% of the market) and some superalloys like IN718. Water atomisation is widely used for stainless steels, but the superalloys demand vacuum inert gas atomisation (VIGA).

The HIP process (Figure 2) consists of filling shaped metallic containers (‘cans’) with powder, which, after evacuation of air and sealing, are hot isostatically pressed, typically at pressures of the order of 1000–2000 bar and temperatures of 1000–1200°C.

Fig. 2.

The HIP process. Reprinted with permission from (4)

This demands a reproducible and high tap density to reduce shrinkage (typically ~10–15%) in pressing and excellent sphericity and smoothness are most desirable to assist in filling shaped cans. Purity is vital, as no changes in oxygen content are possible in HIP. Thus gas atomisation is almost mandatory for this. Particle size is a secondary consideration, although for critical aerospace applications, fine powder, typically <53 μm, is used to ensure no inclusions above this size are possible. Alloys used range from stainless and tool steels to superalloys.

The AM field is rather more varied in its demands, as there are several major processes in use or under very active development (5). The biggest area now is laser sintering, which has various names, but is shown in Figure 3. This demands powders with excellent flow properties, to help spreading of powder into thin layers before sintering, or more accurately welding, the shape of the part to be made. The oxygen content is of interest; while some attempts have been made to use water atomised powders (7), gas atomisation dominates this field. A very important feature is that particle size is tightly restricted to a range variously set as nominally –53 + 20 μm or –45 + 15 μm. Thus the yield in this narrow size range has a major impact on powder production costs.

Fig. 3.

Selective laser sintering process. Reprinted from (6), copyright (2018), with permission from Elsevier

There are other AM processes, which have attracted a lot of attention in the last decade. These use ‘MIM–grade’ powders. One is binder-jetting (Figure 4), where the shape is generated from layers of powder glued together by a binder printed onto each layer of powder.

Fig. 4.

Binder-jetting process. Copyright 3DEO, USA. Reprinted with permission

Another method is a variant of the very commonly used filament deposition technology where a filament of plastic is heated and welded onto a base plate to build the part. In this case, the filament of plastic is loaded with MIM-grade metal powder to a high degree, so that the deposited part resembles a MIM part. In both these cases, the machine does not make finished parts, but feeds a sintering operation where the binder or plastic is burned out and the part sintered to high density (with high shrinkage). The main requirement of these processes of AM are very similar to MIM, although ‘spreadability’ is needed for the binder jetting process.

3. Atomisation Processes

Atomisation is the breakup of a liquid into a fine spray. If done on a molten material, the resulting spray commonly freezes into powder. There are many ways to atomise metal (8), but for the modern manufacturing methods discussed here, the only processes widely used are water and gas atomisation. There is also a combination of these methods, in ultra-high pressure (UHP) water atomisation (7). For all atomisation techniques, the surface tension of the alloy processed is an important determinant of particle size and it is generally found that if Alloy A makes particles with size x% of Alloy B when atomising with one technique, a similar relationship will exist for another. Thus tin is very easy to make as 10 micron powder, but steel is much more difficult.

3.1 Gas Atomisation

The term gas atomisation now covers a number of different techniques. Perhaps the most important variants are air atomisation, inert gas atomisation (IGA) and VIGA.

3.1.1 Air Atomisation

Air atomisation is where both atomisation and melting are carried out in air. Compressed air jets are used to break up the molten metal and often cooling is achieved by sucking large volumes of cooling air through the equipment. This method has been widely used since ~1900 to make tin, lead, aluminium and zinc powders, but also for some copper and copper alloys. It was used for processing Fe-C alloys in the mid 20th century, but is now obsolete. As would be expected, oxygen contents of air atomised powders are relatively high, typically in the range of 1000 ppm–1%. Particle shapes range from irregular for Al, Zn to spheroidal for copper, gold and silver. Particle sizes for Ni, Fe alloys ~50–200 μm, for Sn, Pb, ~10–30 μm.

3.1.2 Inert Gas Atomisation

IGA is where the melt is broken up by inert gas, normally nitrogen or argon and thus protected from oxidation. This was developed in the post-World War II period with melting in air and used for a very wide range of alloys, ranging from Sn and Pb to Au, Ag, Cu, Co, Ni and Fe alloys. The major fields of application for this technique have been powders for thermal spraying, hard facing, brazing, dentistry and more recently HIP, MIM and AM. Oxygen contents can be far lower than air-atomised powders, typically in the range 100–500 ppm, but highly alloy-dependant. Particle shapes are typically spherical, but agglomeration and satelliting can occur. Median particle sizes are typically 30–200 μm for Fe, Ni, Co alloys with the upper limit dictated by the large vessel sizes needed to avoid splatting of still-molten larger droplets on the walls.

3.1.3 Vacuum Inert Gas Atomisation

VIGA is where the melting and pouring of the alloy prior to atomisation is carried out in a vacuum chamber, to allow the production of the most oxidation-sensitive and reactive alloys, especially Fe-, Ni- and Co-based alloys containing Al, titanium and rare earths. This includes ‘superalloys’ such as IN718, maraging steels and M-Cr-Al-Y alloys. This technique was developed from the 1950s and 1960s when there was a push to explore the potential benefits of rapid solidification (RS) to allow the production of more highly alloyed superalloys for aerospace and defence applications (1). This proved to be a very challenging field of application but, after several decades of development, is now absorbing many thousands of tonnes per year of VIGA-produced superalloy powders. This intensive development has meant that the technology lends itself well to producing powders for HIP, MIM and AM. Oxygen contents in the 50–200 ppm range are achievable. Particle shape is, again, spherical with mis-shapes. Particle sizes are as for IGA.

3.2 Electrode Induction Gas Atomisation

Electrode induction gas atomisation (EIGA, Figure 5) is a ‘ceramic-free’ variant of gas atomisation where the stream of melt is not provided by a tundish and nozzle (extremely difficult for Ti, which attacks all possible nozzle materials) but by drip melting an ‘electrode’ (or bar) which is gently rotated to even out the melting process. The profiled induction coil, typically working at very high frequency (>50 kHz) to avoid excessive magnetohydrodynamic forces on the melt, melts the tip of the bar into a generally conical shape and the resulting stream of drops of molten alloy falls into a free-fall gas atomising nozzle.

Fig. 5.

Electrode induction melting gas atomisation. Reproduced with permission from (9). Copyright: Carpenter Additive

The process is now widely used for Ti alloy production, but suffers from the fact that the stream’s location is poorly defined and the melt rate rather slow, typically 10–30 kg h–1. This leads to very high (argon) gas consumption per kilogram of powder and also to a relatively coarse distribution (median 40–100 micron), so yields of fines are poor. Particle shape is fair, but with some satelliting. Purity is excellent if the system is fully vacuum engineered.

3.3 Plasma Atomisation

Plasma atomisation (Figure 6) is a somewhat ambiguous term, but is generally taken to describe the process invented by Pyrogenesis of Canada in 1995 and now widely adopted for the production of Ti and Ti alloy powders. This ceramic-free process consists of feeding a metal wire into the focus of three plasma torches, which melt and then atomise the material.

Fig. 6.

Plasma atomisation. Reproduced with permission from (9). Copyright: Carpenter Additive

The process is not inexpensive as the feedstock is high-cost Ti ‘wire’ (actually several millimetres in diameter) and the productivity is low, typically ~10 kg h–1 but recently claimed to have been raised to over 20 kg h–1. There is now a facility in the USA with ten systems on one site in order to achieve substantial production. Particle shape is very spherical (due to the very low production rate and modest gas flows) and purity excellent.

3.4 Water Atomisation

Water atomisation (WA) is a development of water granulation, which goes back centuries. Molten metal is broken up by high pressure water sprays, typically ranging from 3–20 MPa. Melting is performed in air and atomisation at first took place in an air atmosphere, resulting in very high oxygen contents for steels. Since the mid-20th century, inerting of the atomising chamber has allowed the production of huge tonnages of Fe powder and of a wide range of alloy steels, including stainless and tool steels. It is also widely used for Au, Ag, Zn and Cu alloys and for some types of Ni and Co alloys. Oxygen contents are highly alloy-dependant ranging from 500 ppm for some self-fluxing Ni-Cr- B-Si alloys and Cu alloys to 1% for high manganese steels. Shape is generally somewhat irregular, but is greatly affected by alloy composition and atomising conditions such that apparent densities can range from as low as 20% to ~50% of solid. Particle size for steels range from ~30 μm to 1000 μm, as the rapid quench of the water jets allows larger particles to freeze quickly.

3.5 Ultra-High Pressure Water Atomisation

Ultra-high pressure water atomisation (UHPWA) as its name implies, involves the use of very high water pressures, typically in the range of 100–200 MPa. At such pressures, the water jets are supersonic, moving at velocities of 400–500 m s–1 and atomisation is partly due to the shockwaves around the water jets. It is normally carried out in an inert gas-purged atomising chamber and allows the production of very fine steel powders with median particle sizes around 10 μm. Oxygen contents, due both to the high surface area of such fine powders and to the oxidation potential of the water, are typically in the range of 2000–5000 ppm. Particle shape can range from somewhat irregular to fairly spherical, allowing high tap densities of ~4.5 g ml–1 for MIM grades.

4. Major Factors in Choice of Atomising Technique

The interaction of the demands of the different advanced manufacturing methods of MIM, HIP and AM; and the alloys to be processed, with the characteristics of the major atomising techniques described above, naturally determine the optimum choices for powder production.

For all techniques, yield of powders of the correct size is a vital economic factor. Thus for MIM, the chief concern is to have a very fine powder to promote high sintering activity. Typical specifications call for a median size of ~10 microns with a D90 of 20–30 microns. UHPWA can provide such a powder with a yield of 70–80% from the atomised powder. Gas atomisation struggles to provide more than a 50% yield. Furthermore, one of the main rationales of employing inert gas atomisation, the achievement of low oxygen content, is of less interest for many alloys, particularly stainless steels (~50% of the market), due to the possibility of reducing many oxides in the sintering stage. Thus gas atomisation is most popular for superalloys with less reducible oxides. For HIP, which does not restrict (in many cases) the minimum particle size, nor demand a very fine maximum size (perhaps 100–300 microns) yields are very high, in the range 80–98%. For AM using lasers, which demand a tight distribution typically with max/min ratio of 2.5–3, the breadth of the distribution is critical. Atomised powders generally follow log-normal statistical distributions and can have standard deviations from 1.8 to 2.5 or more. The difference in yields in a 3:1 size range is very great. For 1.8 standard deviation (theoretical, 100% efficiently screened) yield can reach 64%, while at 2.2 standard deviation it falls to ~51%.

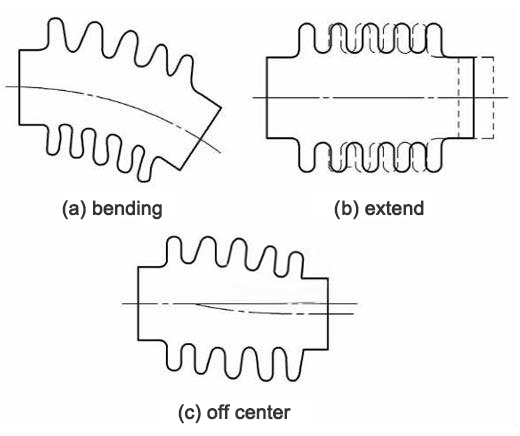

A further important factor is flowability. This is affected by particle shape, which is greatly affected by ‘satelliting’ where smaller particles adhere to larger ones.

Figure 7 and Figure 8 show the effect of an efficient anti-satellite system in gas atomisation (10). This can greatly improve apparent density (for example from ~3.9 g ml–1 to ~4.5 g ml–1 for 53/20 nominal powder) and make the difference between no flow and ~13 s 50 g–1 hall flow rate. Thus gas atomisation with efficient anti-satellite provisions is definitely preferred for all processes demanding good flow properties and high packing density, which include HIP, AM and MIM. Another feature of advanced gas (both IGA and VIGA) atomisers is the use of heated gas which, when applied to the same nozzle and melt flow rate, reduces both gas consumption per kilogram and median particle size with the square root of the absolute temperature, thus greatly improving economics and yields of fine powder (11).

Fig. 7.

Conventional VIGA powder with moderate satelliting. Copyright: Atomising Systems Ltd

Fig. 8.

Gas atomised with anti-satellite system – reduced satelliting. Copyright: Atomising Systems Ltd

The effects of alloys to be processed are also of great importance. Already mentioned is the need for vacuum melting of (Ni-based) superalloys, but for Ti, which reacts with and is degraded by ceramics, ceramic-free melting is mandatory, which has led to the deployment of EIGA and plasma atomisation which, despite their high capital and operating costs and low productivity, have not been bettered for this material.

5. Summary and Conclusions

The more recently developed processes for advanced manufacturing using metal powder, HIP, MIM and AM have different requirements from the previously dominant PM process of pressing and sintering, which is largely served by water atomisation.

For HIP gas atomisation is used, due to the need for clean powder surfaces, with vacuum melting for superalloys. The use of heated gas improves costs and anti-satellite systems can improve flow and packing density.

For MIM, both gas and ultra-high pressure water atomisation are used. The latter is preferred, on economic grounds for many alloys that can be deoxidised in sintering. For more reactive alloys, VIGA production is used. To make the very fine powder sizes needed, hot gas operation is very helpful.

For AM, gas atomisation is almost exclusively used. To improve flow properties, the use of anti-satellite systems is very helpful and hot gas also helps the economics of the process.

References

- 1.

“ASM Handbook: Powder Metallurgy”, eds. P. K. Samal and J. W. Newkirk, Vol. 7, ASM International, Materials Park, USA, 2015, 907 pp

- 2.

B. Williams, Powder Metall. Rev., 2018, 7, (4), 79 LINK: https://www.pm-review.com/wp-content/uploads/2018/12/PM-Review-Winter-2018-single-page-edition.pdf

- 3.

C. Burkhardt, ‘OBE-Metallpulverspritzguss’ [‘OBE Metal Injection Molding’], 2013 LINK: https://commons.wikimedia.org/wiki/File:OBE-Metallpulverspritzguss-Abb4.jpg

- 4.

R. M. German, ‘Fig. 10.18’, in “Powder Metallurgy and Particulate Materials Processing”, Metal Powder Industries Federation, Princeton, USA, 2005, p. 299

- 5.

I. Campbell, O. Diegel, J. Kowen and T. Wohlers, “Wohlers Report 2018: 3D Printing and Additive Manufacturing State of the Industry – Annual Worldwide Progress Report”, Wohlers Associates Inc, Fort Collins, USA, 2018 LINK: http://wohlersassociates.com/2018report.htm

- 6.

H. Sohrabpoor, S. Negi, H. Shaiesteh, I. Ahad and D. Brabazon, Optik, 2018, 174, 185 LINK: https://doi.org/10.1016/j.ijleo.2018.08.040

- 7.

Y. Seki, S. Okamoto, H. Takigawa and N. Kawai, Metal Powder Rep., 1990, 45, (1), 38 LINK: https://doi.org/10.1016/S0026-0657(10)80014-1

- 8.

A. J. Yule and J. J. Dunkley, “Atomization of Melts for Powder Production and Spray Deposition”, Oxford University Press, Oxford, UK, 1994, 397 pp

- 9.

‘Powder Production: Methods of AM Metal Powder Production’, Carpenter Technology Corp, Philadelphia, USA: https://www.carpenteradditive.com/technical-library/powder-production/ (Accessed on 22nd May 2019)

- 10.

J. J. Dunkley and B. Telford, ‘Control of “Satellite” Particles in Gas Atomisation’, World Congress on Powder Metallurgy and Particulate Materials: Advances in Powder Metallurgy & Particulate Materials, Orlando, USA, 16th–21st June, 2002, Part 3: Advanced Materials, Metal Powder Industries Federation, Princeton, USA, 2002, pp. 103–110

- 11.

J. J. Dunkley, ‘Hot Gas Atomisation – Economic and Engineering Aspects’, World Congress and Exhibition on Powder Metallurgy, Vienna, Austria, 17th–22nd October, 2004, The European Powder Metallurgy Association, Shrewsbury, UK, 2004, pp. 13–18