Types and Characteristics of Vacuum Connection Bellows

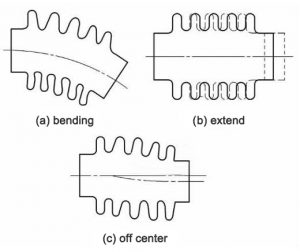

The bellows introduced in this article can be used in ultra-high vacuum systems to achieve bending, expansion and eccentricity (Figure 1), which requires reliable sealing performance and service life of the bellows.

Figure 1 Use form of bellows

Bellows are usually divided into two types: shaped bellows and welded bellows. The material of bellows used in ultra-high vacuum system is generally SUS316 stainless steel.

To make a molded bellow with a slightly larger diameter, first roll the stainless steel plate into a tube shape and weld it at the joint. Insert the cylinder into the bellows mold and complete the production of the shaped bellows by hydraulic pressure.

In the ultra-high vacuum system, the bellows connecting the molecular pump and the mechanical pump are mostly formed bellows with NW flanges at both ends.

The advantages of shaped bellows are simple production and low cost. The disadvantage is insufficient stretch and flexibility. Welding bellows make up for the shortage of molded bellows.

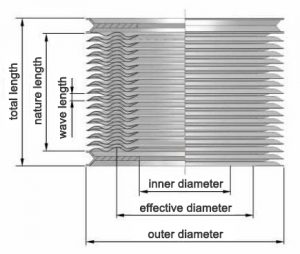

Welded bellows is a thin-walled pleated hose made by welding an annular stainless steel sheet with an inner diameter and an outer diameter alternately (Figure 2). The welding method is plasma welding. This bellows has great flexibility and is an indispensable part in the connection of ultra-high vacuum systems and various motion introducers. Reasonably select the natural length of the bellows, and the service life can reach more than hundreds of thousands of times.